For years, camera engineers have faced a massive design conflict, one we like to call the Heat vs. IBIS Paradox. On one hand, you want a powerful sensor that can shoot 8K video and high frame rates. This generates an immense amount of heat that needs to be moved away quickly to prevent the camera from shutting down. On the other hand, you want In-Body Image Stabilization (IBIS).

To make IBIS work, the sensor is literally suspended in mid-air on a movable stage, isolated from the camera’s chassis by magnetic fields and springs. This isolation breaks the natural path for heat to escape. The sensor becomes a “floating island” of heat with nowhere to go. This is why cameras like the EOS R5 required strict recording limits. Three new patent applications published on December 5, 2025 (JP-2025-176889, JP-2025-176890, and JP-2025-176965) show how Canon may have finally solved this problem.

The Solution: A High-Tech Thermal Bridge

Canon’s solution isn’t to add a bulky fan. Instead, they have re-engineered the connection between the floating sensor and the camera body. Each of the three patents addresses a specific part of this clever thermal bridge.

1. Creating the Path (Patent JP-2025-176889)

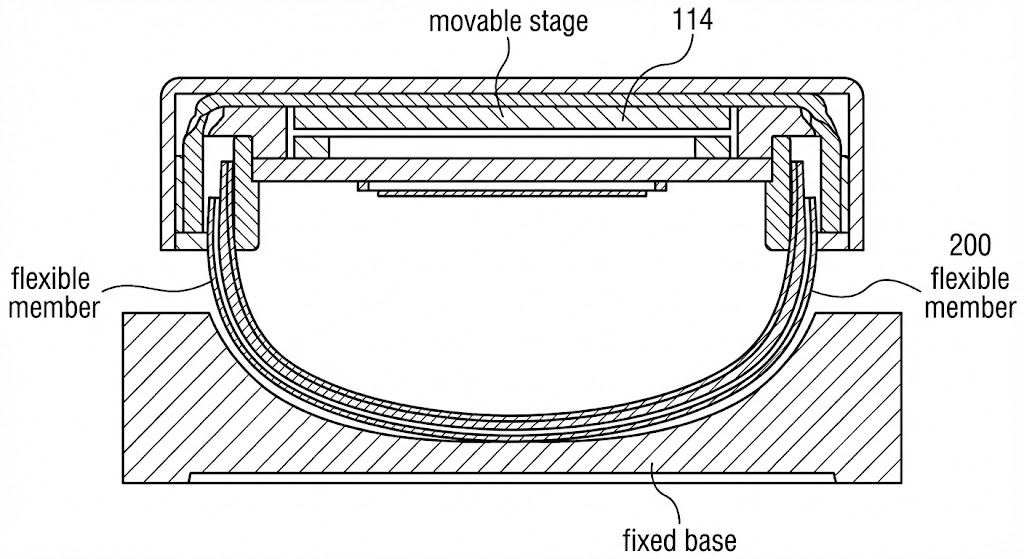

The foundation of the solution is described in patent JP-2025-176889. It introduces a dedicated “flexible member” that physically connects the “movable stage” (the part holding the sensor) to the “fixed base” (the camera’s chassis). Unlike standard ribbon cables that are designed only for data, this component’s primary job is to act as a heat pipe. By re-establishing a physical link, heat can now travel from the sensor to the camera’s large magnesium alloy body, which acts as a giant heatsink.

2. The Magic Material: Graphite (Patent JP-2025-176890)

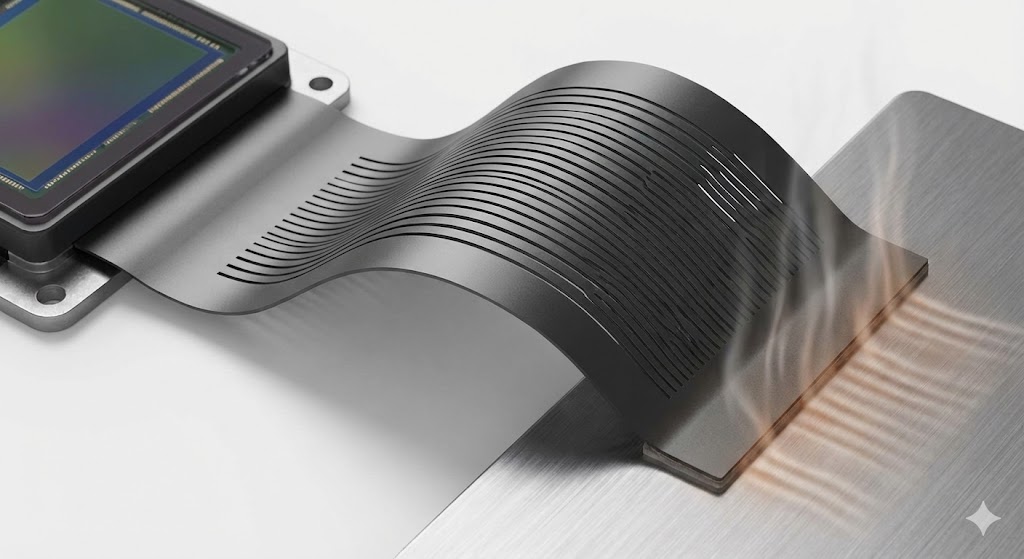

A regular copper wire would be too stiff; repeated IBIS movements would cause it to work-harden and snap. Patent JP-2025-176890 solves this by specifying the use of a Graphite Sheet laminated with PET. Graphite is an incredible material for this application. It has extremely high thermal conductivity—even better than copper in some planes—but is pliable like fabric. This ensures maximum heat transfer without compromising the long-term durability of the stabilization system.

3. Perfecting the Mechanics with Slits (Patent JP-2025-176965)

Even a flexible graphite sheet could offer some mechanical resistance, which would make the IBIS motors work harder, drain the battery faster, and potentially reduce stabilization accuracy. Patent JP-2025-176965 provides the final piece of the puzzle: adding strategic slits (cuts) to the conductive sheet. These slits reduce the sheet’s spring constant, making it ultra-compliant. This allows the heat to flow freely while the sensor moves with zero added resistance, ensuring silky-smooth footage.

Why This Is a Big Deal

This is a passive cooling solution. It doesn’t require a noisy fan or the bulky camera body of something like the EOS R5 C. This technology suggests that future cameras, like a potential EOS R5 Mark III, could maintain the same compact, weather-sealed form factor as their predecessors while offering dramatically improved recording times. Canon seems to have found a way to have its cake and eat it too: pro-level video performance without the thermal baggage.